Plating Barrels

Rugged, Ready, & Resilient

Built rugged for serious applications, BSI starts with polypropylene materials to construct plating barrels that withstand harsh chemicals year after year. BSI builds barrels for nearly any chemical. Sizes range from 12" x 24" to 26" x 60" barrels. We also do side-by-side barrels for rack applications.

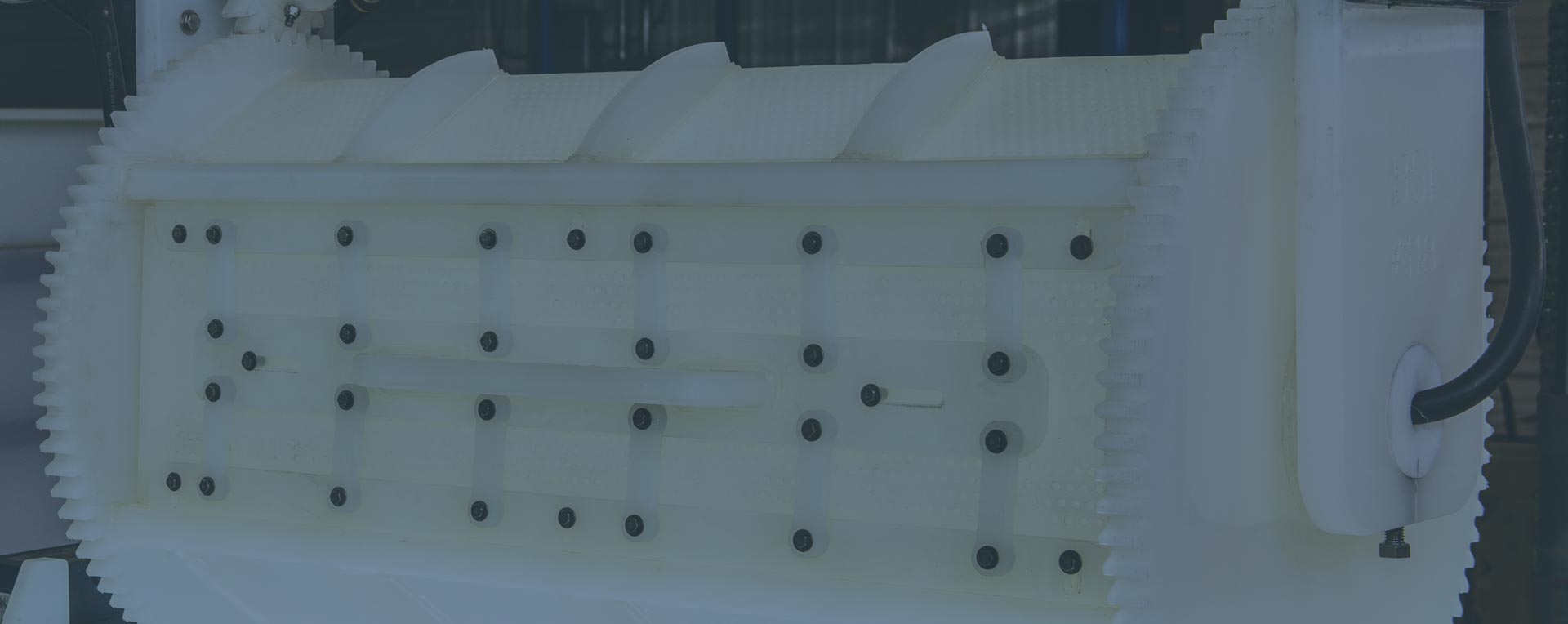

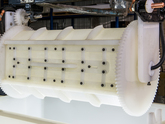

BSI barrels feature dual drive gears welded to each end of the cylinder for additional strength. This eliminates lengthy interruptions from chipping. If a tooth chips, simply flip the barrel and use the other gear. For easier cylinder installation and removal, bearings are installed from the inside and mounted securely to the hanger with a titanium bolt.

Whatever your process calls for, BSI will equip you with the quality barrels needed for a beautiful finish.

LOCK-JAW: A Breakthrough in Plating Barrel Doors

Designed to reduce cycle time and eliminate load loss, the LOCK-JAW features our convenient grab handle for one-handed installation and removal. The LOCK-JAW prevents warping for increased lifespan of the door. Its dual-side locks improve barrel performance by securing all parts while the drum operates. Available with slots to reduce drag out or made with hole perforations ranging from 1/2" – 1/16", BSI’s LOCK-JAW is an innovation in ease-of-use plating barrel doors.

“Our door ribs are cut on an angle this gives the door a much tighter seal so parts don’t get stuck in the door when plating.”

1. PARTS DON’T GET STUCK

To help keep parts from sticking in barrel we have a bearing system that has a sleeve around it to keep the parts from getting stuck around the bearing.

2. EASY BUSHING REPLACEMENT

We also have a nice system for the drive end of the barrel. We know bearings don’t get greased like they should and it is a lot of trouble to replace bushings, but not with ours! We use a 4 bolt bearing system that can be easily replaced in a matter of minutes.

3. NO MORE STRIPPED KEYWAYS

Now let’s discuss plastic drive gears. The problem with most plastic drive gears is that when you put a lot of weight in the barrel the keyway will strip. Not with ours, we make our barrels with a bolt that goes through the plastic and the drive shaft that holds it in place. If a bolt breaks you can change it without taking it off the line, by simply spinning the barrel until the holes line up and then putting a new bolt in place.

4. WE DOUBLE THE GEAR LIFE

On our barrels we make the gear part of the head, unlike others; we put it on both sides. The reason our competitors don’t do this is if a tooth breaks, you have to buy a new barrel or send it to them to repair it. But with a gear on each side you can simply take the bearings out and turn the barrel around using the other side, giving you TWICE THE USAGE of the barrel.

Photo Gallery